Iridium is a critical component of proton exchange membrane (PEM) water electrolyzers, which major industry players are beginning to manufacture at large scale. PEM electrolyzers rely on iridium oxide catalysts, straining the supply chain of one of the rarest naturally-occurring elements on Earth.

Iridium saw a spectacular price rally in 2021 after supply shortages and expectations it will be used to produce hydrogen to power a greener economy lifted its value by 160% in two months.

A by-product of platinum and palladium mining, iridium is vital for many industries and can also serve as a catalyst in electrolysis to split water into oxygen and hydrogen, which is increasingly in demand as a cleaner source of power than fossil fuels.

Mattiq said it undertook, leveraging AI technology, the world’s most comprehensive study of iridium alternatives to enable cost-effective PEM water electrolysis with improved supply chain resiliency. Each alternative, it said, has the potential to meet or exceed that material’s performance, but with a much lower cost and greater availability.

Iridium’s limited supply and high cost has stirred debate in the planning of infrastructure, such as hydrogen hubs, to meet future demand for clean hydrogen.

“Mattiq’s approach fills a major unmet need; it is important not just for the future of clean hydrogen but also for the rapid development of a wide range of chemicals on the road to electrification and decarbonization,” Carmichael Roberts, Mattiq’s board director, co-founder and managing partner of Material Impact and investment co-lead at Breakthrough Energy Ventures, said in this week’s statement.

Mattiq CEO Jeff Erhardt has spent years building deep tech software startups around analytics, machine learning, and artificial intelligence applied to traditional and heavy industry.

One of those companies he sold to Microsoft and another to General Electric, where he was executive vice president, Intelligent Systems & Industrial AI from 2017-2019.

“Key enabling materials — could be cobalt, could be platinum, could be iridium — are critical to the energy and climate transition going forward,” Erhardt told MINING.com.

“There is simply this massive mismatch in what’s needed or projected [in] the world’s demand for green hydrogen production,” Erhardt said. “In the specific catalyst is actually a radium oxide, and there’s something like 10 times difference in what the world has projected for its needs of green hydrogen production.”

Erhardt said that in this space, there are some catalyst materials that are intuitive and known to work, and others that are less intuitive that haven’t been researched.

“Our unique capability is we don’t have to pick one, and experiment one at a time because we can run so many experiments at the same time, millions of different combinations.”

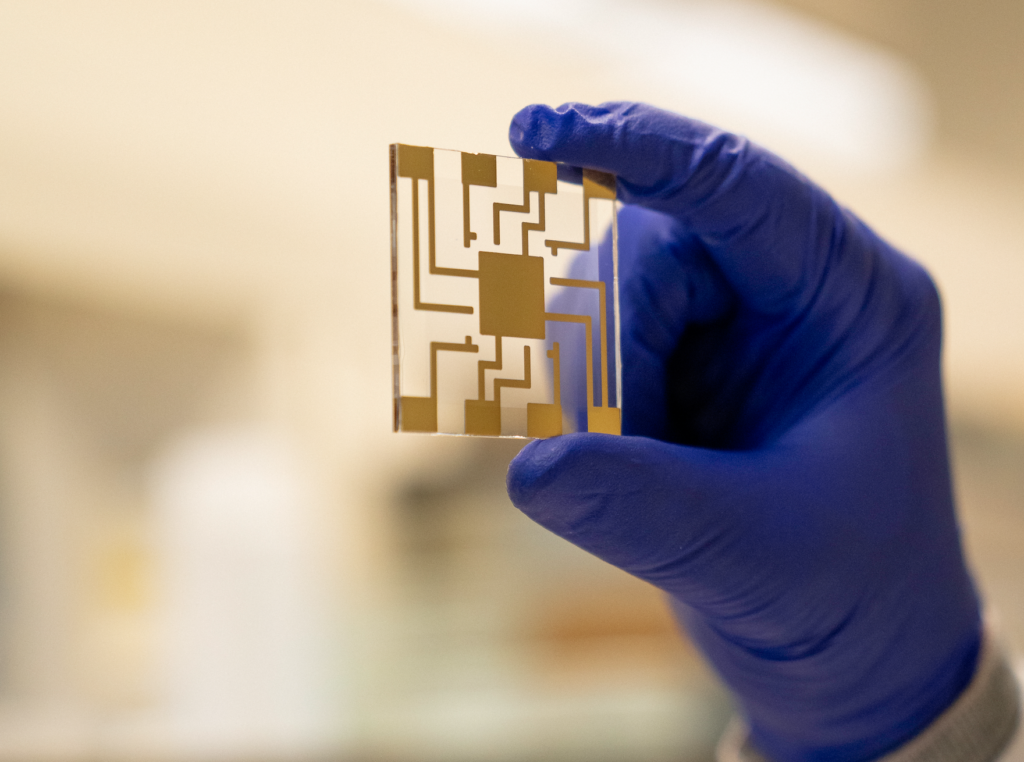

“Our core technology is very similar to what’s done in drug discovery and genomics. [What] people did with the genome chips a decade or so ago was they synthesized millions of molecular candidates on a single chip, characterize them, and then put them into a drug development pipeline to radically transform the way that drugs were developed and fine-tuned for specific people in specific conditions,” Erhardt said.

“That’s exactly what we’re doing in this material space. We have a core technology that allows us to synthesize on a chip the size of your thumbnail millions of individual inorganic nanoparticles where we can control the composition of those, the size and the shape.”

Erhardt said it took a team of just under 20 researchers about six months to produce the portfolio of viable alternatives, and that a portfolio of patents is currently pending.

“We [have] the ability to combine these different elements, whether they’re rare earths, whether they’re common metals and combine them in unique ratios and structures, we can unlock sort of unexpected properties that people couldn’t have predicted ahead of time,” he said.

Erhardt said the team explored the entire periodic table of elements during the research phase.

“We validated all these internally, including reliability and robustness and we have been working with multiple different industrial partners,” he said. “As we start to bring these to market, some of them will be surprises and are things people have never considered before.”

The company is targeting the first quarters of 2024 to bring the portfolio of materials to market.

This article was published by: Amanda Stutt

Visit the original article here